We hope you love the products we recommend and just so you know that as an Amazon Associate EngineHoist.net may earn from qualifying purchases.

An engine lifter is a small cylinder you might hear about when you’re studying car mechanics or fixing a car problem.

So what is an engine lifter?

Sitting between a car’s camshaft and cylinder valves, it has a simple but crucial role. As the camshaft spins, it pushes the lifter, opening the valve for a short while. It’s interesting that the intake and exhaust valves open at different times, and each one has its own lifter.

Even though engine lifters may seem simple, understanding what they do helps you get a full understanding of how your car works.

Let’s explore more about what is an engine lifter and how it operates to make their role easy to understand.

What is an Engine Lifter?

Engine lifters, also known as valve lifters or tappets, are crucial components of your vehicle’s internal combustion engine.

Essentially, these are small cylinders located in the engine block that interact with the camshaft to control the opening and closing of the engine’s valves.

This regulated valve action is what allows the correct mix of air and fuel into the engine, as well as letting exhaust gases out.

Car Lifter Basics

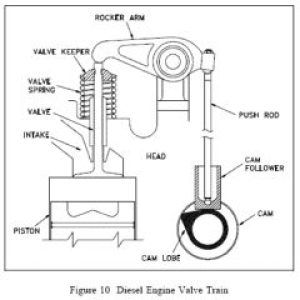

In the realm of internal combustion engines, there are many components working harmoniously, and the lifter is no exception. Its role is to act as a link between the camshaft and the engine valves. As the camshaft rotates, it rides over the lifters, causing them to move up and down. This movement subsequently opens and closes the valves in sync with the engine’s operational rhythm.

It’s worth noting that engine lifters can vary depending on the type of engine. For instance, in pushrod engines, lifters activate a rocker arm that presses on the valve, whereas in overhead cam engines, the lifter can sometimes directly actuate the valve.

Types of Lifters: Hydraulic and Mechanical

There are two main types of engine lifters: hydraulic and mechanical, each with its own unique attributes and use cases.

Hydraulic Lifters

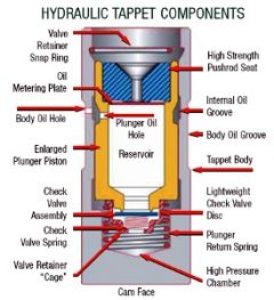

Introduced in the 1930s to reduce the noise from older mechanical lifters, hydraulic lifters quickly became a popular choice. They have an internal piston and are designed to maintain zero valve clearance for quiet and efficient operation.

When the camshaft acts on the hydraulic lifter, it forces oil out of the lifter, causing it to compress and the valve to open. Once the camshaft lobe rotates past its peak, the lifter piston expands again, allowing oil to flow back in, and the valve to close. This cycle repeats with each rotation of the camshaft.

However, precision is key with hydraulic lifters. If engine RPMs are too high, the lifter may not fully re-pressurize, leading to poor engine performance. Over-pressurized lifters, on the other hand, may not fully close the valves, leading to potential engine damage.

Mechanical Lifters

Mechanical lifters, also known as solid lifters, offer a simpler and more reliable design, particularly suited to high-performance applications where engine RPMs are often higher. They operate on a direct mechanical linkage, with clearance between the camshaft and the lifter that needs to be set manually, often referred to as valve lash.

Mechanical lifters are available in two main types: solid and roller lifters. Solid lifters are just a solid metal cylinder that moves up and down with the camshaft’s rotation. Roller lifters, on the other hand, feature a roller that interfaces with the camshaft, reducing friction and wear, and improving high-RPM performance.

Lifters in Variable-Displacement Engines

Variable-displacement engines, or engines that deactivate cylinders under light load for improved fuel efficiency, pose unique challenges for lifters. Since these engines switch off cylinders when not required, it’s crucial for the corresponding valves to remain closed, preventing unnecessary air pumping and energy loss.

There are multiple ways to achieve this, but one common method is the use of advanced hydraulic lifters that can collapse when the cylinder is deactivated.

This means the camshaft won’t actuate them, and the valves remain closed. Control of these operations is handled by the powertrain control module (PCM), ensuring automatic, seamless transitions in response to driving conditions.

Troubleshooting Lifters

Like any other engine component, lifters can develop issues over time. Identifying problems early on can prevent more serious engine damage. Symptoms of a failing lifter may include a ticking or knocking noise from the engine, reduced engine performance, or even a check engine light.

Remember, if you suspect a lifter problem, it’s best to consult with a professional mechanic. They have the necessary expertise to diagnose and fix the problem accurately and safely.

Summary

Engine lifters may be small, but their role in ensuring the smooth, efficient operation of your vehicle’s engine is substantial.

From hydraulic to mechanical, their type and operation can vary, but their purpose remains constant: to manage the crucial opening and closing of engine valves.

Understanding the function and importance of these components can help you make more informed decisions about your vehicle’s maintenance and troubleshooting.

Stay tuned for more informative articles to delve deeper into the fascinating world of car mechanics!